In a pair of reports today, DigiTimes claims that Apple's manufacturing partner Foxconn is experiencing shortages of both labor and component supplies required for iPhone and iPad production, with Apple also being among the companies still scrambling to secure component supplies in the face of increasing supply chain tightness resulting from the Japanese earthquake that has seen suppliers nearly run through any cushion they may have had.

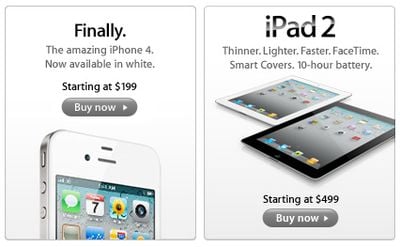

Taiwan-based electronics manufacturing service (EMS) provider Foxconn Electronics (Hon Hai Precision Industry) is reportedly facing a shortage of both labor and materials at its plants in Chengdu, China, which is likely to affect shipments of iPad 2 and iPhone 4 orders in the second quarter, according to sources from upstream component makers.

According to the reports, Foxconn had planned 52 iPad production lines at its Chengdu plants capable of pumping out a total of at least 40 million units per year, but the component shortages and labor issues have meant that the manufacturer is falling short of Apple's current demands for 2.5-3 million units per month.

The component shortages stemming from the effects of the Japanese earthquake and the resulting country-wide power issues are said to have led to electronics manufacturers seeking to stockpile existing supplies of components while attempting to play down those moves lest suppliers realize the extent of the shortages and increase prices.

The sources pointed out that PC- and smartphone-related players have all claimed to have not seen any supply issues after the earthquake because of concerns that it might cause upstream players to panic and even raise their product prices, while trying to prevent the subject from impacting their new product launches. However, most of these makers have all been working on stocking their component inventory behind the scenes, the sources added.

The sources noted that several component suppliers are already close to having shortages with the real challenge expected to hit in June. The shortage crisis is also expected to bring issues such as rising costs and an increased rate of defective products in the future.

Apple shipped 4.69 million iPads during the first quarter of 2011, well below what most observers were expecting. The shortfall was reportedly due to the production transition from the original iPad to the iPad 2, with several technical challenges including light leakage on displays from LG and speaker production issues also affecting shipments.

Top Rated Comments

Good idea, won't happen though (sadly) :(

That said, I don't understand why I should want someone in China to be unemployed just so an American can have a job. They're human beings with families to feed. I also don't necessarily want my children to toil away in a factory. I feel bad for the Chinese that have to.

2) That would not solve the availability of components. It's a shortage

3) All products would become more expensive if produced in the US.

Even when people say, I would pay more, they usually don't!

4) This discussion was already held in other threads. Many of the US laws are not conducive to building factories here.

By the time a State or area would be done with just the environmental review other countries built the plant already.

Add capital gains taxes, unions etc. etc. and you'll know why these plants are not here.

5) The type of labor the assembly of millions of pieces requires is not available in the US. (See Cato Institute studies)

The higher education workers will not do these jobs. The lower education workers we don't want near these jobs.

The majority of manual labor is almost in the hands of the hispanic community, who do this well.

(On a sarcastic note, ask an American worker to lift a few heavy boxes and they'll call OSHA to have it automated or pass a regulation)

"Buy American or produce American" is a patriotic phantasy and doesn't account for the fact that Americans have many jobs in importing and exporting, as well as work internationally. If all the countries would isolate themselves only doing "home based" production, innovation would stifle and we'd go backwards.

The concept of FREE enterprise should apply to everybody all over the world.

The business world is now heavily integrated and in the very end it's all about money and profits and share prices.

Nobody pays anybody for being "nice" and giving jobs!

Reality hurts:-)

+1

Id love Apple to be a positive example of American made electronics. Id definitely feel more at ease to paying their higher prices, if so.

And, let's say they don't what then?

Factories shouldn't be built based on thinking it will go on positively forever.

I think the US auto industry has demonstrated that clearly.

People act as if owning a factory is easy. (I actually own a small factory, so I know it's not.

I am in a niche field and easily compete with the Far East))

Apple would have to add substantial personnel to manage such a place, which takes away from what they really want to do. (Build great devices people want to buy)

It is far easier NOT to own a factory. You buy whatever you need at an agreed upon price when you need it. And when you don't have anything you need, you don't have a factory and workers to worry about.

If you have issues with your suppliers you work with them to fix them or you go to another manufacturer.

Try that with your own place. QC is bad, get another manager, QC is still bad get another one etc.

You are never in the driver's seat when you own a factory!

The overall wages workers would be paid aren't even the problem. The administration, laws, unions, taxes etc. are what makes it undesirable to own a factory.

Plus, any slightest mishap or work issue would be on the front pages of all the magazines.

Apple is a smart company , hence no factory in the US!