TSMC 2nm Chip Production Hits 60% Yield, on Track for iPhone 18 Pro

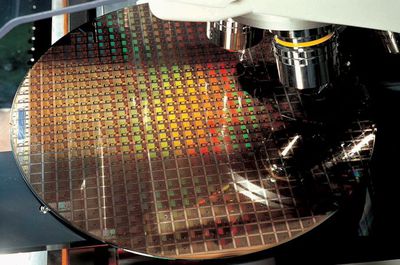

TSMC has achieved better-than-expected results in trial production of its 2-nanometer chip technology, with yield rates exceeding 60%, according to Taiwanese supply chain sources (via Liberty Times Net). The news suggests the company is well-positioned to begin 2nm mass production in 2025, which could see its use in Apple's iPhone 18 Pro models the following year.

The semiconductor manufacturer is reportedly conducting risk trial production at its Baoshan facility in Hsinchu, northern Taiwan, where it has implemented a new nanosheet architecture that promises a significant advancement over the current 3nm FinFET process. The company plans to transfer this production experience to its Kaohsiung plant for mass manufacturing, according to the report.

TSMC's progress bodes well for Apple, with a September report from analyst Ming-Chi Kuo and a more recent rumor claiming that Apple's 2026 iPhone 18 Pro models will exclusively feature chips built on TSMC's 2nm process and 12GB of RAM. The standard iPhone 18 models are expected to continue using an enhanced 3nm process due to cost considerations.

The 2nm process is said to be generating substantial interest from potential customers, particularly in the AI sector. Indeed, company CEO C.C. Wei has noted unexpectedly high demand for the upcoming 2nm technology, suggesting production at scale will be ramped up as soon as is possible to meet that demand.

TSMC's roadmap includes the 2026 introduction of an A16 process (1.6nm-class – not to be confused with Apple's chip nomenclature), which will combine Super Power Rail (SPR) architecture with nanosheet transistors. SPR is expected to provide an 8% to 10% performance increase at the same voltage and complexity, a 15% to 20% power demand decrease at the same frequency and transistor count, and a 7% to 10% chip density increase, depending on the design.

Popular Stories

Apple is looking for a "breakthrough" with its push into wearable AI devices, including an "AirTag-sized pendant," according to Bloomberg's Mark Gurman.

In a report this week, he said the pendant is reminiscent of the failed Humane AI Pin, but it would be an iPhone accessory rather than a standalone product.

The pendant would feature an "always-on" camera and a microphone for Siri voice...

Apple Watch is now eleven generations in, and packed with useful features that are easy to miss at first glance. To help you get more out of your new device, we've rounded up 15 practical tips you might not have discovered yet, including a few that long-time users often overlook.

Bounce Between Two Apps

On your Apple Watch, double-press the Digital Crown to see a deck of all currently...

Apple's iPhone development roadmap runs several years into the future and the company is continually working with suppliers on several successive iPhone models at the same time, which is why we often get rumored features months ahead of launch. The iPhone 18 series is no different, and we already have a good idea of what to expect for the iPhone 18 Pro and iPhone 18 Pro Max.

One thing worth...

New trade-in data indicates that Apple's iPhone 17 Pro Max has rapidly become the single most traded-in smartphone.

According to a new report from SellCell, Apple's latest flagship iPhone has quickly risen to the top of the independent trade-in market, accounting for 11.5% of all devices appearing in the top-20 trade-in rankings just months after release. The analysis is based on SellCell...

Apple will announce its rumored low-cost MacBook at its event on March 4, with the device coming in a selection of bold color options, according to a known leaker.

Earlier this week, Apple announced a "special Apple Experience" for the media in New York, London, and Shanghai, taking place on March 4, 2026 at 9:00am ET.

Posting on Weibo, the leaker known as "Instant Digital" said that the...

![]()