Apple has shared a new Paper and Packaging Strategy white paper, outlining steps the company takes to reduce its paper impact by using paper more efficiently, sourcing it responsibly, and protecting or creating sustainable working forests.

To protect the environment for the future, Apple said three priorities guide its efforts:

1. Reduce impact on climate change by using renewable energy sources and driving energy efficiency in products and facilities.

2. Conserve precious resources by using materials efficiently, using more recycled and renewable content in products, and recovering material from products at the end of their life.

3. Identify, develop, and utilize safer materials in products and processes.

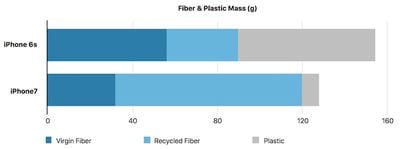

The change in iPhone packaging from iPhone 6s to iPhone 7 illustrates the significant impact of Apple's efforts.

While the iPhone 6s packaging included two stacked plastic trays that hold the device and accessories separately, Apple came up with a new design for the iPhone 7 packaging that allows a single tray to do the work of two. Eliminating the second tray significantly reduced the packaging's material footprint.

Apple's environmental teams also found a fiber-based material that could be used to make the trays, replacing the petroleum-based plastic previously used. The white paper says a similar exploration of new materials and design led to innovations in the EarPods carrier, further reducing the use of materials.

For the iPhone 6s, Apple designed a plastic EarPods carrying case that discreetly wraps the cables and holds the headphones in place. For the iPhone 7, however, Apple developed a more environmentally friendly paperboard-based solution with a set of folds and cuts that secure the EarPods and cable.

These changes contributed to an 84 percent decrease in plastic usage for iPhone 7 packaging compared with iPhone 6s, according to Apple.

For the iPhone 8, Apple even sourced a more environmentally friendly alternative to the plastic wrap that protects the iPhone's wall charger. Apple's white paper reveals the meticulous steps it took to achieve this feat, which involved working directly with a supplier to alter aspects of the manufacturing process.

Finding a fiber alternative proved challenging since fiber naturally expands and contracts with changes in humidity. The significant number of suppliers and locations through which the power adapter wrap would pass made controlling the humidity of the environment impossible. This required Apple to take a very hands-on approach, working directly with the supplier to alter aspects of the manufacturing process to create a fiber wrap that would meet technical needs. While the power adapter wrap is a small piece of the iPhone packaging, it represents a significant amount of material given the number of iPhone units sold.

Ultimately, Apple said it hopes that its program highlights a process for others to take responsibility for their impact on global resources, and work with external stakeholders to protect the environment.